Clark GEX 40/45/50

Stand-Up Counterbalance

How can we help?

(317) 487-1400

Features

-

Less downtime

-

Reduces truck travel speed in turns

-

Built with long life lining material

-

Rivals IC truck performance in speed, acceleration and gradeability

-

Silent staging reduces shock and vibration

-

GEX 40/45/50 can accommodate 72 kwh battery

-

Provides added traction, especially on wet or uneven surfaces

-

The operator can select from 4 pre-set performance modes

-

Suitable for Wet Applications

-

CLARK moved back the steer axle, dropped the battery compartment and moved all major components lower

-

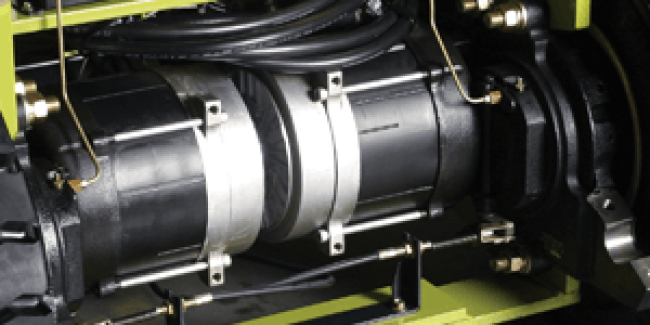

Drive Motors & Axles

-

Easily Serviced

-

Supported on gas springs for easy service access from a standing position

-

Higher voltage = lower line loss & heating = greater efficiency

-

Only requires one receptacle via single battery connector

-

Indicates the current alarm code and stores previous alarm codes for quick access

-

Powered Reversing Drive Motors

-

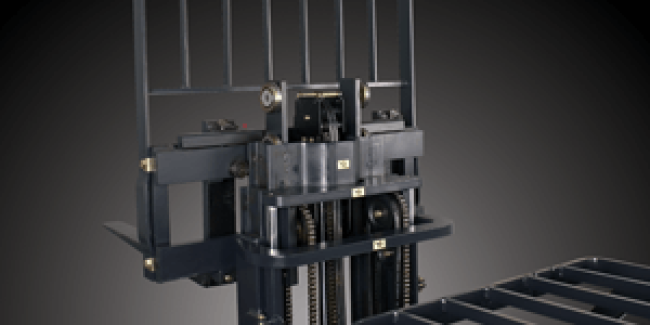

Carriage has 6 rollers to maximize load distribution and reduce free play

-

Nested I-channel allows space for cylinders, hoses and chains

-

80 Volt 100% AC System

-

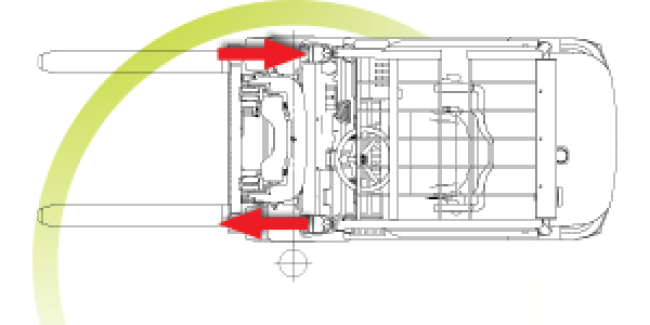

Inside wheel power reverses in tight turns preventing scuffing of steer tires like conventional 4-wheel trucks

-

Enclosed, brushless

-

Regen & Wet Disc Brakes

-

Stable Platform

-

LCD Dash Display

-

Thermal and stall protection

-

Service brake (Foot brake)

-

Dual/powered reversing for tighter turns

-

Change of direction (Proportional to accelerator position)

-

Upright & Carriage

-

Enclosed and oil cooled for smooth, quiet operation

-

Relays steer tire position to control

-

Provides excellent lateral stability

-

Certain adjustments can be password protected to allow only authorized operators to make adjustments

-

Accelerator release (Proportional to accelerator position)

-

Same motors for E & EE

-

Allow servicing mechanic to check fault codes without service tool